Calculation of poultry house ventilation + calculation formula

Calculation of poultry house ventilation + calculation formula

Proper ventilation in poultry houses is of great importance. This process has a direct impact not only on the health and well-being of birds, but also on their production performance. Fresh and clean air provides the oxygen needed for birds to breathe and prevents the accumulation of harmful gases such as ammonia. The main purpose of ventilation systems in poultry houses is to maintain optimal temperature, humidity and air quality to maximize bird growth and production. In this article, you will learn how to calculate poultry house ventilation.

Table of Contents

- Calculation of poultry house ventilation

- Evaporative cooling system (pad and fan)

- Tunnel ventilation: an efficient solution for poultry house cooling

- Key points in designing and implementing poultry house ventilation system

- Alvand Industrial Group, fresh air for your poultry house

Calculation of poultry house ventilation

Proper ventilation is a key factor in the success of poultry farming. Accurate calculation of the required ventilation rate in the house helps to maintain the health of the birds and increase productivity. There are two main methods for calculating the ventilation of the poultry house:

1. Hall Area Based Method

In this method, the required ventilation rate is determined based on the hall area and type of bird. The larger the hall area or the greater the number of birds, the more air is needed. To calculate the number of fans required, first the required air volume of the hall is determined in cubic meters per hour and then the number of fans required is calculated based on the capacity of each fan.

Calculation formula

Air requirement per second: Hall cross-sectional area * 2 meters per second

Air requirement per cubic meters per hour: The value obtained in the previous step * 3600

Example:

Assume we have a poultry hall with an area of 100 square meters. To calculate the number of fans required with a capacity of 44,000 cubic meters per hour, first we calculate the amount of air required according to the poultry house fan calculation formula as follows:

Cross-sectional area (assuming the height of the hall is 3 meters): 100 * 3 = 300 square meters

Air volume required in seconds: 300 * 2 = 600 cubic meters per second

Air volume required in cubic meters per hour: 600 * 3600 = 2160,000 cubic meters per hour

Number of fans required: 2160,000 / 44,000 ≈ 49 fans

If you need a heater for your poultry house, you can go to the poultry house jet heater page for more information and to complete it.

2. Bird Weight Based Method

In this method of calculating the ventilation of a poultry house, the total weight of the birds in the house is the basis for the calculation. Each bird requires a certain amount of air to breathe and excrete metabolic gases. Considering the total weight of the birds and the specific conversion factor, the amount of air required for the house is calculated and the number of fans required is determined. This calculation method is also applicable to livestock ventilation in large and small livestock farms.

Calculation formula

Amount of air required: Total weight of birds * 60 * 0.00075 * Maximum temperature of the area in Fahrenheit

Example:

Assume that 1000 chickens with an average weight of 2 kg are kept in a poultry house. The maximum temperature of the area in the warm season is 35 degrees Fahrenheit and the capacity of each fan is 44000 cubic meters per hour.

Total weight of birds: 1000 chickens * 2 kg/chicken = 2000 kg

Calculate the amount of air required: 2000 kg * 60 * 0.00075 * 35 = 3150 m3/h

Calculate the number of fans required: 3150 m3/h / 44000 m3/h/fan ≈ 0.07 fan

According to the calculations, for this poultry house with the mentioned specifications, about 0.07 fans are required. Since we cannot install a fraction of a fan, we will need at least one fan with a capacity of 44000 m3/h.

Factors affecting the ventilation rate

In addition to the area of the house and the weight of the birds, other factors also affect the ventilation rate of the house:

Age of the bird: Young chicks need warmer air and more humidity, while adult birds want cooler and drier air.

Bird density: Increasing bird density in the house requires more ventilation.

Fan type: The capacity and efficiency of the fans affect the ventilation rate of the house.

Number of inlet windows: Inlet windows play an important role in bringing fresh air into the house.

Geographical region: The climatic conditions of the region, especially temperature and humidity, affect the amount of ventilation required.

Accurate calculation of poultry house ventilation is essential to maintain bird health and increase productivity, such as poultry inlet. There are two main methods for this calculation: based on house area and based on bird weight. Factors such as bird age, density, fan type and weather conditions also affect the amount of ventilation.

Evaporative Cooling System (Pad and Fan)

Evaporative cooling or pad and fan system is one of the most common and effective methods for cooling poultry houses in hot and dry areas. This system uses cellulose pads and exhaust fans to convert hot and dry air into cool and humid air.

How it works

Cellulose pads act like a sponge and absorb water. As hot and dry air passes through these humid pads, the water evaporates and takes the latent heat of evaporation from the air. As a result, the air temperature decreases and is directed into the house. Exhaust fans also circulate the cooled air by creating negative pressure in the house and direct the hot air out.

How is the fan power calculated? What is the formula? You can go to the relevant article to answer all your questions.

Calculating the required pad size

To calculate the required pad size, first determine the air discharge capacity of the fans. Then, using the formula for calculating poultry house ventilation, the required pad area is calculated. In general, the greater the air discharge capacity, the greater the pad area should be.

Relationship between air discharge capacity and pad area

Pad area = (air discharge capacity) / (constant coefficient)

The constant coefficient in this formula depends on various factors such as the type of pad, pad thickness, and weather conditions.

Using a pad and fan system, a suitable and controlled environment can be provided for poultry farming and losses due to heat stroke can be prevented.

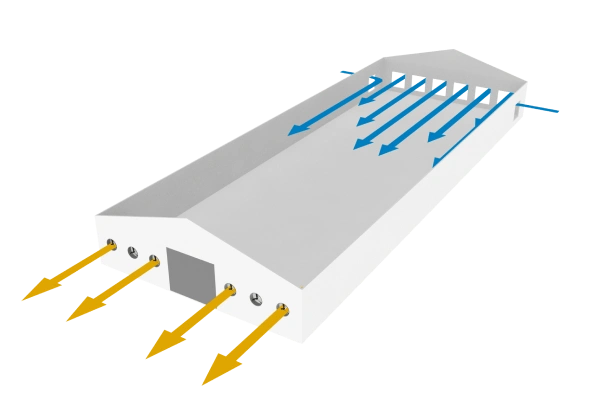

Tunnel ventilation: an efficient solution for cooling poultry houses

Tunnel ventilation is one of the effective methods for creating a favorable environment in poultry houses, especially in hot and dry areas. In this system, air flows uniformly and at a certain speed throughout the house.

Working principles

Uniform air flow: By installing powerful fans at both ends of the hall, hot and polluted air is sucked in from one side and fresh air is introduced from the other.

Evaporative cooling: Cellulose pads are used to increase the relative humidity of the air and reduce its temperature. As the hot air passes through the cellulose pads, it absorbs moisture and cools down.

Advantages of tunnel ventilation

Uniform air distribution: This system ensures that all parts of the hall are ventilated evenly and prevents the creation of hot and cold spots.

Reduced energy consumption: By using cellulose pads, the need for mechanical cooling systems is reduced.

Improved air quality: Tunnel ventilation reduces the concentration of ammonia, dust and other air pollutants.

Calculation of fan capacity and pad size

To accurately calculate the fan capacity and pad size required for a specific house, parameters such as house dimensions, ambient temperature, relative humidity, and bird type must be considered. For example, for a house with specific dimensions, the fan capacity and cellulose pad area can be calculated using engineering formulas.

Numerical example

Assume that we have a poultry house with dimensions of 100 meters long, 10 meters wide, and 4 meters high. Considering the climatic conditions of the region and the type of bird, the fan capacity can be considered as 12,000 cubic meters per hour and the cellulose pad area can be considered as 100 square meters.

Tunnel ventilation is an efficient and cost-effective method for creating a suitable environment in poultry houses. With the correct design and implementation of this system, it is possible to improve bird performance, reduce losses, and increase production.

Tunnel ventilation is an efficient method used to cool poultry houses, not only reducing energy consumption but also improving air quality. To calculate the ventilation of a poultry house and the required equipment, various parameters such as the dimensions of the house and environmental conditions must be considered.

Conclusion

In this article, we discussed how to calculate the ventilation of a poultry house. Various factors such as the area of the house, the weight of the birds, the type of fan, and the weather conditions affect the amount of ventilation required. Evaporative cooling systems (pads and fans) and tunnel ventilation were also introduced as effective methods for cooling houses. To ensure the correct design and implementation of the ventilation system, it is recommended to benefit from the advice of experienced experts in this field, such as Alvand Industrial Group. By properly implementing the ventilation system, it is possible to improve bird performance, reduce losses, and increase productivity in the poultry farming industry.

Alvand Industrial Group, Fresh Air for Your Poultry

Are you looking for the best equipment for your poultry house? Alvand Industrial Group, with years of experience, offers a wide range of ventilation, heating and cooling products to create an ideal environment for your birds. From powerful fans to efficient heaters, all Alvand products are manufactured with the highest quality standards. By choosing Alvand, benefit from the unparalleled warranty and after-sales service of this collection. Also, for advice and purchase, contact Alvand experts now.

2025-01-13

2025-01-13 32 minute

32 minute

0 comment

0 comment