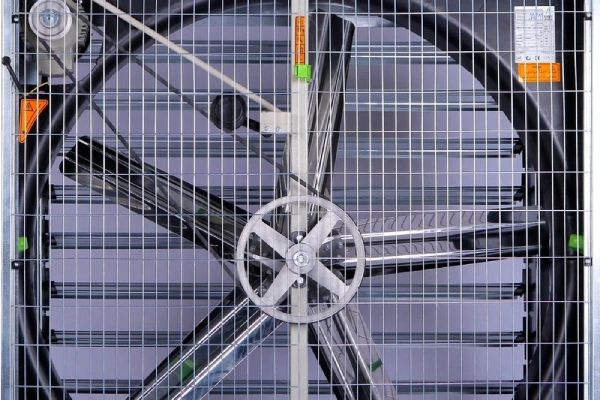

How to install a poultry house fan + installation instructions

Proper ventilation in poultry farms is one of the most important factors affecting the health of birds and production efficiency. Fresh and clean air, proper humidity, and controlled temperature provide ideal conditions for the growth and development of birds. The lack of proper ventilation can lead to the spread of diseases, reduced production, and increased mortality. The purpose of writing this article is to provide step-by-step instruction on installing and operating a poultry farm ventilator. By reading this article, you can easily install your poultry farm ventilator and enjoy its benefits.

Table of Contents

- Selecting and Preparing a Poultry Fan

- Step-by-Step Guide to Installing a Poultry Fan

- Common Problems and Solutions in Poultry Technology

- Conclusion

- Alvand Industrial Group: A Guarantee for Quality and Durability

Selecting and Preparing a Poultry Fan

Choosing the right location for installing a poultry fan is a key factor in providing proper ventilation and maintaining the health of the birds. In general, there are three ways to install a poultry fan:

- Transverse walls: In this method, fans are usually installed at a height of about one meter from the floor and in the transverse walls of the hall. Air inlets are also placed on the opposite wall or at the ends of the two longitudinal walls. This method is suitable for halls with a length of less than 70 meters and creates a direct and simple air flow.

Longitudinal walls: In this method, fans are installed in the longitudinal walls and against the wind direction to use natural ventilation. Air inlets are also installed in the opposite wall. This method is suitable for halls with a standard width. However, in wider halls, air distribution may not be good and it may be necessary to use air outlet vents in the ceiling.

Ceiling: Installing fans in the ceiling is usually done in hot or cold areas. In hot areas, fans are placed in the ceiling and air inlets are placed in the longitudinal walls to remove hot air from the hall. In cold areas, the location of the fans and vents is reversed to prevent cold air from entering the hall.If you are a greenhouse owner or want to start one, you must have come across the question of how to cool a greenhouse. You can go to the article in question to answer your questions.

Reviewing the advantages and disadvantages of each method

Each of the methods mentioned has its own advantages and disadvantages, which we will review below:

Installing a wall fan

Advantages

Easier installation: The installation process of wall fans is relatively simpler and requires less equipment.

Lower cost: Due to the ease of installation and less equipment required, the cost of installing wall fans is usually lower.

Disadvantages

Improper air distribution: In some cases, installing a wall fan may cause improper air flow and not fully ventilate the hall. This is especially observed in large halls or halls with complex geometric shapes.

Limited ventilation capacity: Due to the physical limitations of the wall, the ventilation capacity of wall fans is usually less than that of ceiling fans.

Impact on the appearance of the building: Installing a wall fan can affect the appearance of the building and is not aesthetically pleasing.

Installing a ceiling fan

Advantages

Uniform air distribution: Installing a ceiling fan allows air to be distributed evenly throughout the hall and prevents dead spots.

Higher ventilation capacity: Ceiling fans usually have a higher ventilation capacity than wall fans.

Reduced humidity and dust: By creating a stronger air flow, ceiling fans help reduce humidity and dust in the hall.

Disadvantages

More complex installation: Installing ceiling fans requires more expertise and equipment and is usually more time-consuming.

Higher cost: Due to the complexity of the installation and the equipment required, the cost of installing ceiling fans is usually higher.

Limited access for maintenance: Ceiling fans are more difficult to access for maintenance.

Step-by-step guide to installing a poultry house fan

It’s time to install the fan. Stay tuned for a complete tutorial on installing the fan and fan.

Preparation before installation

Safe transportation: Carry the fan carefully to avoid damage.

Installation location: Make sure the installation location is large enough. For example, for a 140 cm fan, a space of 1420 x 1420 mm is required.

Tools and equipment: Before starting work, prepare all the necessary tools and equipment such as screwdrivers, wrenches, drills, drills, silicone adhesive, wiring, on/off switches, etc.

Steps for installing a wall fan

Determining the exact location: Mark the installation location on the wall and make the necessary holes using a drill.

Connecting the fan to the wall: Place the fan in the intended location and secure it in place with a roll-up screw.

Connecting the power cords: Connect the fan’s power cords to the electrical junction box and be sure to get help from a skilled electrical technician and ensure that safety precautions are followed, such as wearing gloves and turning off the power while working.

Sealing: Seal the area around the fan’s connection to the wall with silicone adhesive to prevent dust and insects from entering.

Ceiling fan installation steps

Creating an opening: Create an opening in the ceiling the size of the fan.

Installing the fan: Place the fan in the opening and secure it to the ceiling using bolts or special fasteners.

Connecting the power cords: The steps for connecting the power cords are similar to wall installation.

Sealing: Seal the area around the fan’s connection to the ceiling with silicone adhesive.

Important installation tips

Installation height: Install the fans at a height where the blades are at least 230 cm from the floor.

Wiring: The fan wiring should be done by a qualified electrician.

Grounding: Connect the fan ground wire to the building grounding system.

Rust prevention: Avoid using corrosive materials to clean the fan.

Performance test: After installation is complete, check the fan operation and monitor the direction of rotation of the impeller, its noise level and vibration.

Common problems and solutions for poultry fans

Common problems with poultry fans and their solutions are diverse. Common problems include the following:

- Reverse motor rotation: This problem usually occurs due to incorrect electrical wiring. This problem can be solved by reversing the phases.

Reduced ventilation: Various reasons such as loose belts, blocked blades, or damaged dampers can cause reduced ventilation. The problem can be solved by checking and repairing these parts.

Severe vibration: Causes of severe vibration include blade imbalance, loose screws, or damaged internal parts. This problem can be solved by balancing the blades and tightening the screws.

Motor failure: Several reasons such as power outages, motor burnout, or damaged electronic components can cause the motor to stop working. The problem can be solved by checking the electrical circuit and replacing the faulty parts.

Abnormal noises: Abnormal noises may be caused by worn parts, loose screws, or unbalanced blades. This problem can be solved by checking and repairing the faulty parts.

General Solutions to Poultry Fan Problems

Regular Inspection: Periodically inspect and repair fans.

Cleaning: Clean the blades and other fan parts regularly.

Lubrication: Lubricate the moving parts of the fan regularly.

Timely Repair: If any problems occur, repair or replace the defective part promptly.

Conclusion

Proper installation of poultry house fans is a vital step in maintaining the health of birds and increasing productivity. Choosing the right type of fan is very important, based on various factors such as the size of the house and the number of birds, and how to install the poultry house fan. Studies have shown that properly installed fans can increase bird growth by up to 15%. Also, an incorrectly installed fan can increase energy consumption by up to 30%. By following these tips, you can ensure that your poultry house ventilation system works optimally and, consequently, your productivity and profitability will increase.

Alvand Industrial Group: A guarantee of quality and durability

Alvand Industrial Group is one of the reputable and leading manufacturers of industrial cooling, heating and ventilation equipment in Iran. This group, using state-of-the-art technology and using quality raw materials, produces and supplies a variety of products including industrial fans, poultry jet heaters and other equipment. One of the prominent features of Alvand products is the one-year warranty and 10-year after-sales service, which shows the company’s confidence in the quality of its products. To purchase products, contact the experts of this collection.

2024-12-18

2024-12-18 30 minute

30 minute

0 comment

0 comment